In Service Application

We have highly experienced knowledgeable and skilled technical team in application of NDT in maintenance and shut-down projects. Our experience is ranging from simple application of conventional NDT methods with modified conventional techniques and advanced NDT techniques. In-service inspection needs sometimes creative and out of box thinking in utilizing available accessibility and modifying the technique to achieve the effective results. This needs sometimes special fixtures to access and withstand high temperatures (if any). This also includes positive detectability by enhancing detection and eliminating false calls. Our approach is extensively based on planning and modelling approach using available softwares (CIVA etc.,).

Conventional NDT application

• MSL Service provides inspection covering conventional NDT methods such as.

• Eddy current Inspection for surface crack detection.

• Liquid penetrant testing for surface crack detection.

• Magnetic particle testing for surface and sub-surface crack detection.

• Ultrasonic Testing for welds and other products.

• Radiography Testing for welds and other products.

• Visual Testing for welds and other products.

Corrosion Monitoring

• Corrosion monitoring for cross country piping and process piping is one of the most important maintenance activity.

• This needs a continuous monitoring of the corrosion growth to access the remaining life or service of product before decision to change.

• MSL Service provide the following techniques for corrosion monitoring in application of storage tanks, pressure vessels, piping and structures.

• Conventional ultrasonic testing for normal and high temperature application

• Conventional radiography testing for corrosion evaluation

• Digital radiography testing for corrosion monitoring

• Advanced UT (encoded) inspection on normal and high temperature application. We have special scanner to assist in fast scan and provide reliable and consistent results.

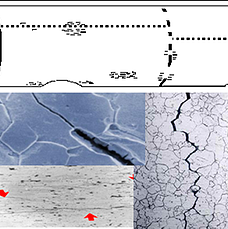

Hydrogen induced cracking

• Hydrogen induced corrosion is one of the prominent process induced defect which results infailure of component in-service.

• Detection of HIC needs a special process, procedure, equipment and skill of operator.

• MSL Service provides inspection solution using encoded PAUT technique using proper accessories for reliable and effective results.

• This can be applied on normal temperature and hot surface conditions.

For noisy materials(Austenitic SS), we provide special phased array probes (dual matrix array Transmit-Receive L wave(DMA TRL) probe application.

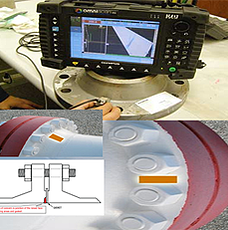

Flange Inspection

• Corroding or loss of sealing area can cause loss of containment therefore potential for catastrophic release with loss of assets, production and injury to personnel.

• Flange seat crevice corrosion using PAUT technique has been a proven technique in detection of such corrosion as part of maintenance program.

• MSL Service applies a special probes and calibration procedure to assure effective results.

The Group of Quality

"MSL Group delivers quality, on schedule, and safe projects at a competitive price."

Works Services : Electrical & Instrumentation Works, Piping Pre-fabrication and Erection Works,

Maintenance Services, Manpower Supply Services, NDT Training and Services

MSL has recently extended its services to include the Piping works in our portfolio. MSL has been awarded the first contract for piping works for FMC project located in Pluak Daeng, Rayong.

MSL also partnered with the A-Star Training and Consultancy of Singapore to become A-Star (Thailand) to further provide :

Training in NDT, Consultancy in NDT, NDT Products